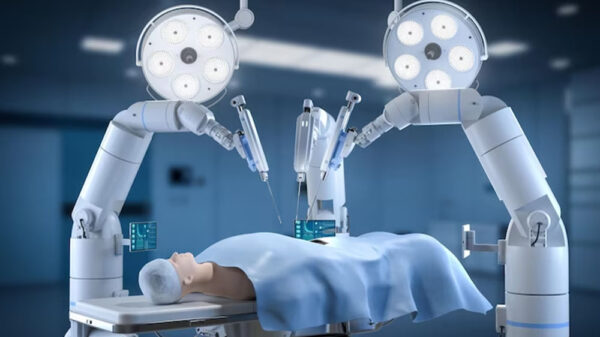

In the world of logistics and supply chain management, the role of robotics has become increasingly significant. Robotic warehouses, in particular, have revolutionized the way goods are stored, retrieved, and transported. These automated systems have the potential to streamline operations and improve efficiency. However, the coordination of multiple robots in a warehouse environment can be complex and challenging.

Recognizing this, researchers at MIT have developed a groundbreaking neural network architecture that aims to enhance operations in robotic warehouses. The focus of this innovation is on efficiently coordinating groups of robots, with the ultimate goal of speeding up decongestion in such environments.

The Challenge of Coordinating Robots in Warehouses

Robotic warehouses are designed to handle large volumes of goods and fulfill orders with precision and speed. However, as the number of robots increases, so does the complexity of coordinating their movements. This can result in congestion, delays, and inefficiencies.

Traditionally, warehouse robots are programmed to follow predefined paths and avoid collisions with each other. While this approach works to some extent, it lacks adaptability and real-time decision-making capabilities. As a result, congestion can occur when multiple robots converge on the same area or when unexpected obstacles arise.

The AI Model: Enhancing Efficiency and Decongestion

The AI model developed by MIT researchers addresses these challenges by leveraging advanced neural network architecture. The model is designed to enable real-time coordination and decision-making among groups of robots, allowing for efficient movement and decongestion in the warehouse.

At the core of the AI model is a deep reinforcement learning algorithm. This algorithm enables the robots to learn from their environment and make intelligent decisions based on the current situation. By continuously observing and analyzing the state of the warehouse, the robots can adapt their movements to avoid congestion and optimize efficiency.

The AI model also incorporates a centralized controller that oversees the actions of all robots. This controller acts as the brain of the system, receiving information from each robot and providing high-level instructions. By centralizing decision-making, the model ensures that robots work together seamlessly, minimizing conflicts and maximizing productivity.

The Benefits and Implications

The development of this AI model holds significant implications for the future of robotic warehouses. By improving coordination and reducing congestion, the model can enhance overall efficiency and productivity. This, in turn, can lead to faster order fulfillment, reduced costs, and improved customer satisfaction.

Additionally, the AI model has the potential to adapt to changing warehouse environments. As new obstacles or challenges arise, the model can learn and adjust its strategies accordingly. This adaptability ensures that the system remains effective and efficient in dynamic and evolving warehouse settings.

Furthermore, the AI model can be integrated with existing robotic warehouse systems, making it a practical and scalable solution. By leveraging the power of AI and machine learning, warehouses can unlock new levels of efficiency and performance.

The Future of Robotic Warehouses

MIT’s AI model for robotic warehouses represents a significant step forward in the field of logistics and automation. As technology continues to advance, we can expect further innovations that improve the coordination and efficiency of robotic systems.

With the potential to revolutionize the way goods are stored, retrieved, and transported, robotic warehouses are poised to play a vital role in the future of supply chain management. Through advancements like MIT’s AI model, we can unlock the full potential of these automated systems and create a more efficient and streamlined logistics ecosystem.